Advanced Plastic Additive Masterbatches für die Feuchtigkeitskontrolle und Schaumbildung bei der PolymerverarbeitungVerbesserung der Produktionseffizienz und der Materialleistung bei mehreren Harztypen

Unser Sortiment an Polymer-Additiv-Masterbatches umfasst spezielle Formulierungen wie Plastic Defoamer Masterbatch und CaO Desiccant Masterbatch, die für die Kompatibilität mit HDPE, LDPE, LLDPE, PP entwickelt wurden,Diese Zusatzstoffe lösen die häufigen Herausforderungen in der Kunststoffherstellung, insbesondere für Anlagen, die entweder recycelte oder neu entstandene Polymere verwenden.Das Vorhandensein von Restfeuchtigkeit führt häufig zu Defekten in den Fertigprodukten, wie zum Beispiel zu Blasen., Oberflächenstreifen, Risse oder unebene Texturen, die traditionell energieintensive Vortrocknungsverfahren erfordern.

Durch die Einbeziehung unserer Masterbatches direkt in den Rohstoff in einem empfohlenen Verhältnis von 1% bis 5% können die Hersteller zusätzliche Trocknungsschritte vermeiden.Durch diesen vereinfachten Prozess werden nicht nur Energie und weniger Arbeitskräfte eingespart, sondern auch die Produktionszyklen verkürzt und die Gesamtbetriebskosten gesenktDas Masterbatch ist so konzipiert, dass es sich nahtlos in bestehende Prozesse wie Spritzgießen, Filmblasen und Extrusion integrieren lässt.ohne Änderung der Ausrüstungseinstellungen oder der Endproduktmerkmale.

Dieses aus Polyethylen, Calciumoxid und Calciumcarbonat bestehende Trocknungsmittel ist ungiftig, geruchlos und sicher zu handhaben.Es beginnt mit der Aktivierung bei Temperaturen zwischen 130°C und 140°C und bleibt 12~24 Stunden nach der Exposition gegenüber Luft wirksam.Seine alkalische Beschaffenheit (pH ≥ 7) sorgt für Kompatibilität mit Polyolefinen und Polystyrol, während sein Schmelzflussindex (130 g/10min) eine gleichmäßige Dispersion innerhalb der Polymermatrix ermöglicht.

Technisches Datenblatt

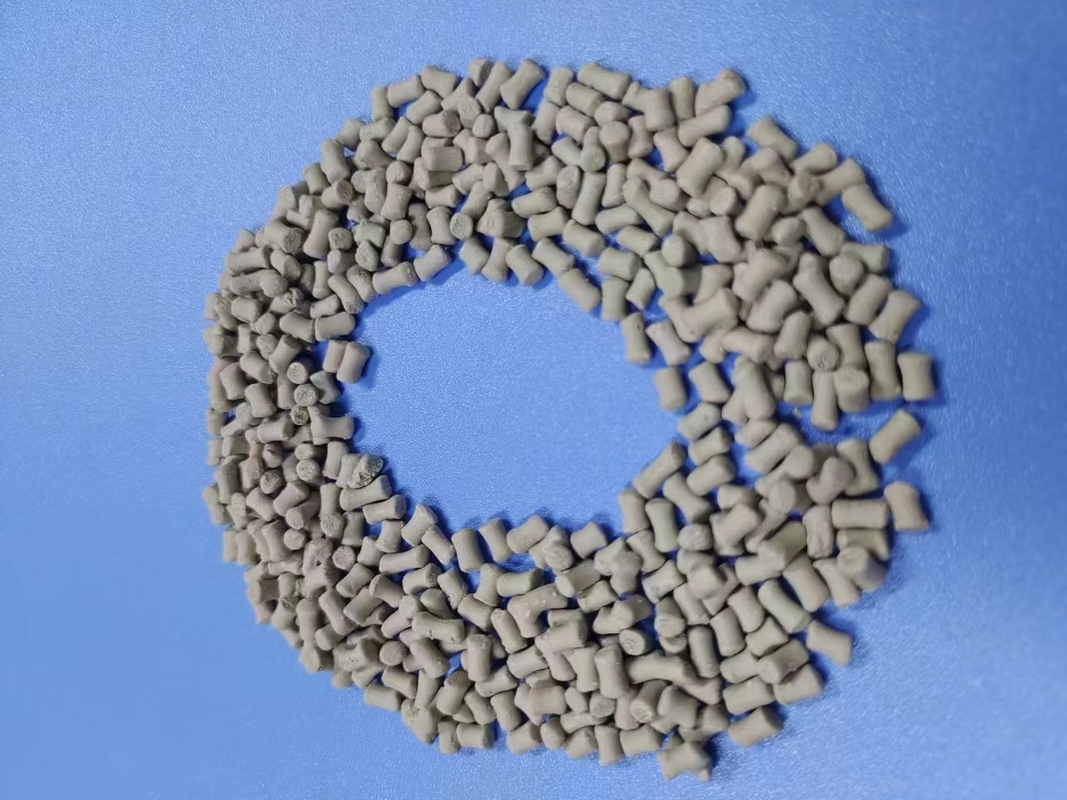

| Farbe |

Graue Harzpellets |

| Formular |

Granulat |

| Zulassung |

Filmqualität |

| Empfohlene Verwendungsquote |

1% bis 5% |

| Kompatible Verfahren |

Spritzgießen, Blasgießen, Filmauspressen usw. |

| geeignete Polymere |

PE, PP, PS, PVC, ABS, HIPS, GPPS, TPU und mehr |

| Hauptbestandteile |

PE, CaO, CaCO3 |

| Schmelzpunkt |

130°C-140°C |

| Haltbarkeit nach Öffnung |

12 bis 24 Stunden nach dem Öffnen der Beutel |

| Funktion |

Entfernen der Feuchtigkeit in Kunststoffrohstoffen |

| PH-Bereich |

≥ 7 |

| Schmelzindex |

1 bis 30 |

| Wirkstoff |

50 bis 80% oder mehr |

Anwendung

Warum mit uns zusammenarbeiten?

- Kundenservice mit 24-Stunden-Behandlung

- Umfangreiche Expertise in der Entwicklung und Anwendung von Masterbatches

- maßgeschneiderte Lösungen auf der Grundlage spezifischer Kundenanforderungen

- Direktfertigung ohne Zwischenhändler und Gewährleistung wettbewerbsfähiger Preise

- Modernste Produktions- und Qualitätskontrollinfrastruktur

- Schnelle Produktionsumstellung und kostenlose Probenangebote

<<<++++ ++++>>>

<<<<<<<<<<

Ich bin nicht derjenige, der das Problem hat.

+++

F: Wie kann ich die Qualität der Proben bewerten?

A: Wir liefern kostenlose Proben nach Bestätigung des Interesses. Versandkosten können anfallen oder im Voraus bezahlt werden.

F: Wie lange dauert Ihre typische Reaktionszeit für Angebote?

A: Das Angebot wird in der Regel innerhalb von 12 Stunden erteilt.

F: Wie wird die Produktqualität gewährleistet?

A: Wir führen strenge Rohstoffprüfungen durch, überprüfen sie während des Prozesses und testen die Endprodukte.

F: Sind Sie Hersteller oder Händler?

A: Wir sind ein direkter Hersteller mit eigenen Produktions- und F&E-Fähigkeiten.

F: Welcher Schiffshafen wird genutzt?

A: Lieferungen werden in der Regel über den Hafen von Shenzhen versandt.

F: Wie lange dauert die Produktionszeit?

A: Die Lieferzeiten variieren je nach Auftragsvolumen und spezifischen Anpassungsanforderungen.

F: Ist die Musteranpassung verfügbar?

A: Ja, wir stellen kundenspezifische Proben zur Verfügung, um spezifische Material- oder Verarbeitungsbedürfnisse zu erfüllen.

F: Welche Polymere sind mit Ihren Masterbatches kompatibel?

A: Unsere Produkte sind mit einer Vielzahl von Thermoplasten kompatibel, darunter PE, PP, PVC, ABS, PS, HIPS, GPPS, TPU und mehr.

F: Wie werden die Preise ermittelt?

A: Die Preise basieren auf der Bestellmenge und den Spezifikationen der Verpackung.

+++

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!